About this project

In 1797, the Conewago Canal kicked off the construction of Pennsylvania's Canal system. The canal system was primarily used as a means of transportation for people and materials. After several decades the interlocking sections of canals grew to reach 1,243 miles throughout the state.

What we did

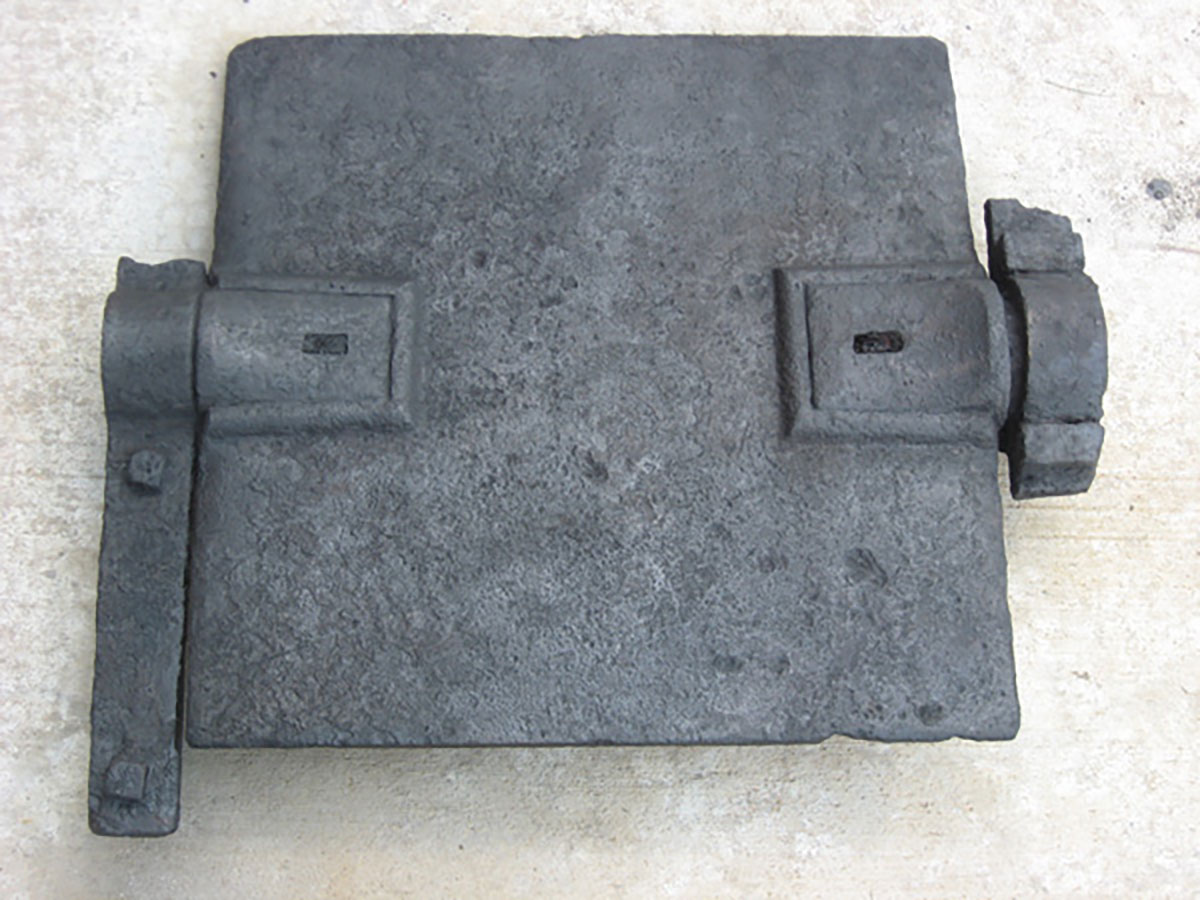

Heberling Associates, Inc. worked under a contract with Pennsylvania Department of Transportation to perform an extensive culture resources study of the Lewistown Narrows prior to the reconstruction of a 10 section off of route 22/322 along the Juniata River. During the investigative study, a portion of canal wall and cast iron lift lock gate was discovered. BRH was contracted to perform a conservation treatment of the lock gate.

The lock gate was submerged in a tank containing deionized water and soaked for many weeks with water replaced every 3 days to reduce the chloride contamination. Initially the chlorides were recorded at over 200 parts per million, but was eventually lowered to under 30 part per million over the course of treatment. The gate lock was then submerged in a new tank. A 5% solution of sodium hydroxide and was connected to a cathode of the rectifier to run a 15 amp current. Stainless steel was used as the sacrificial anode during the electrolytic reduction process. The remaining loosened corrosion product was mechanically removed using metal picks and brushes. A 2% tannic acid solution was applied to the surface followed by a hot waxed coating which was impregnated with carbon black pigments