Military artifact conservation

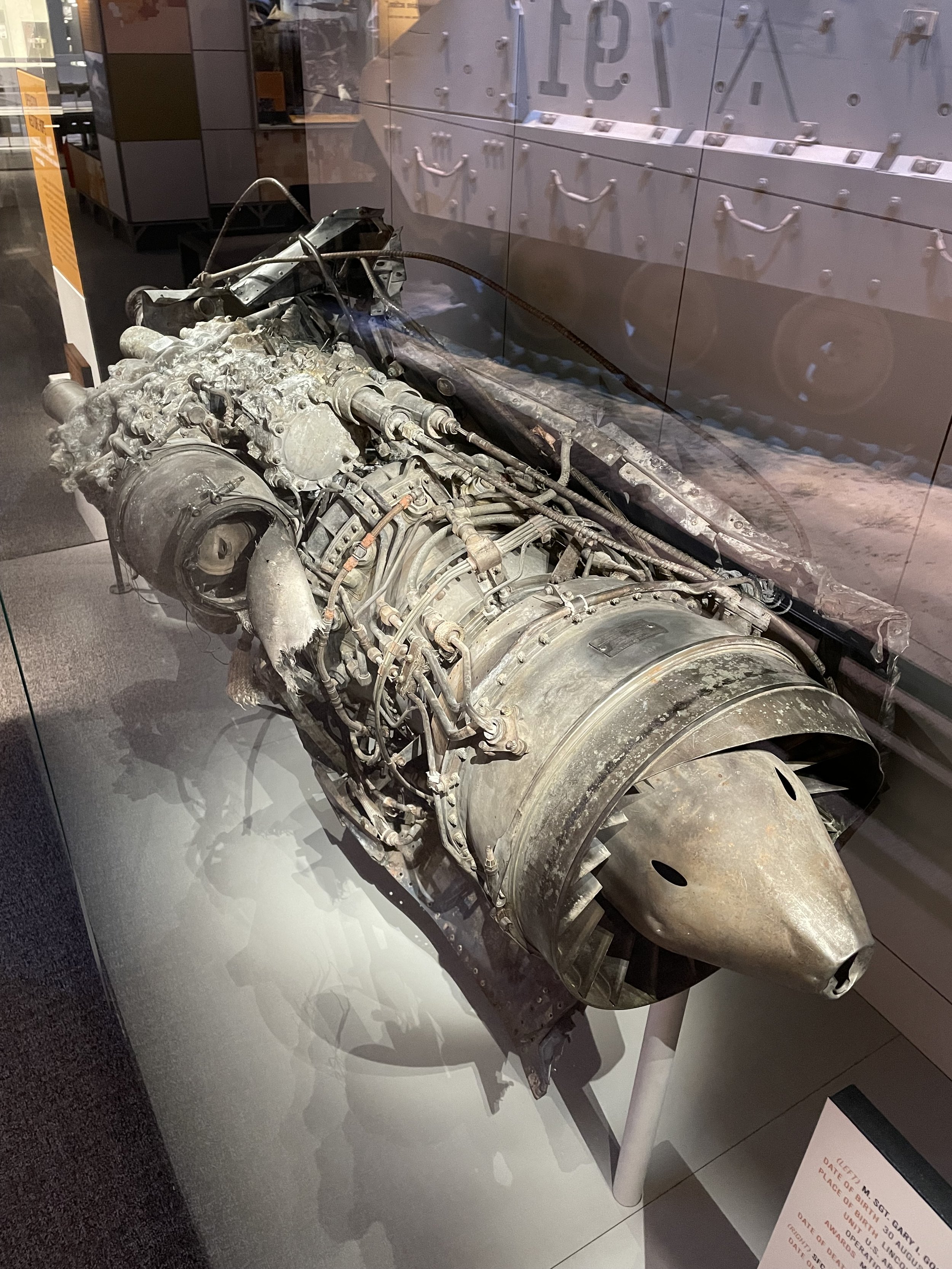

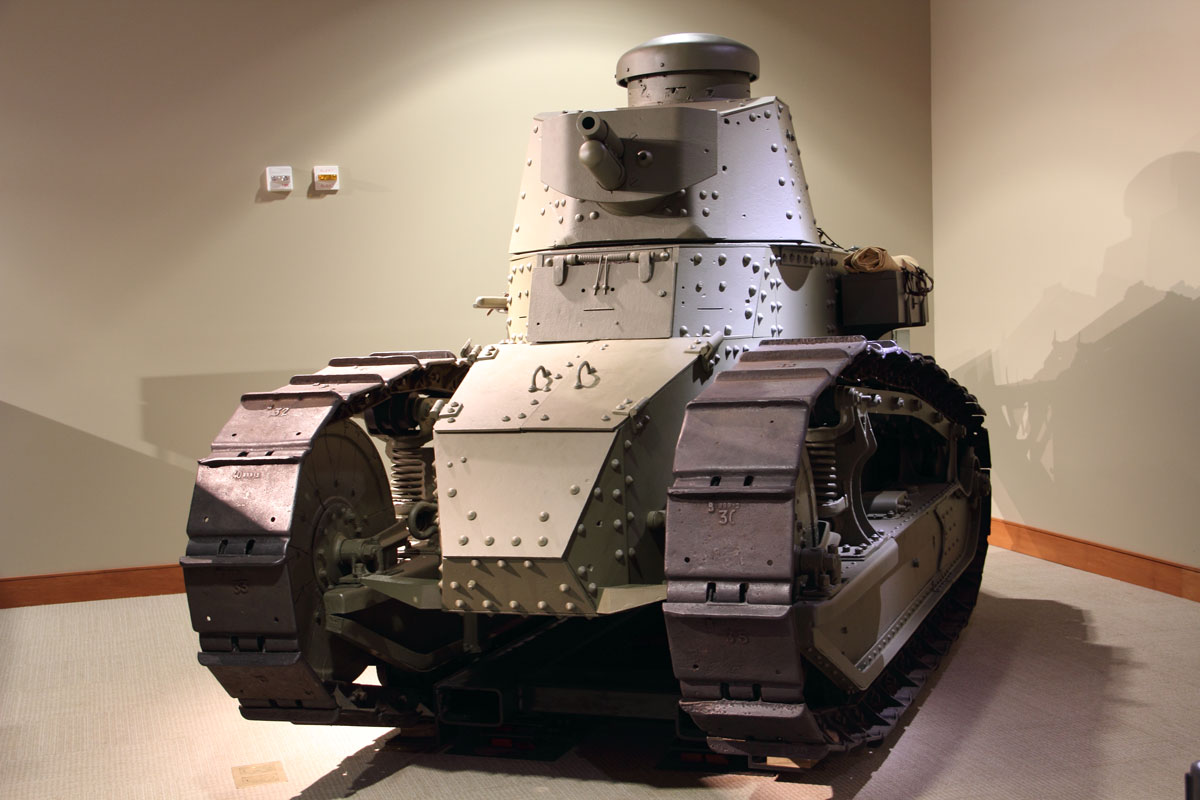

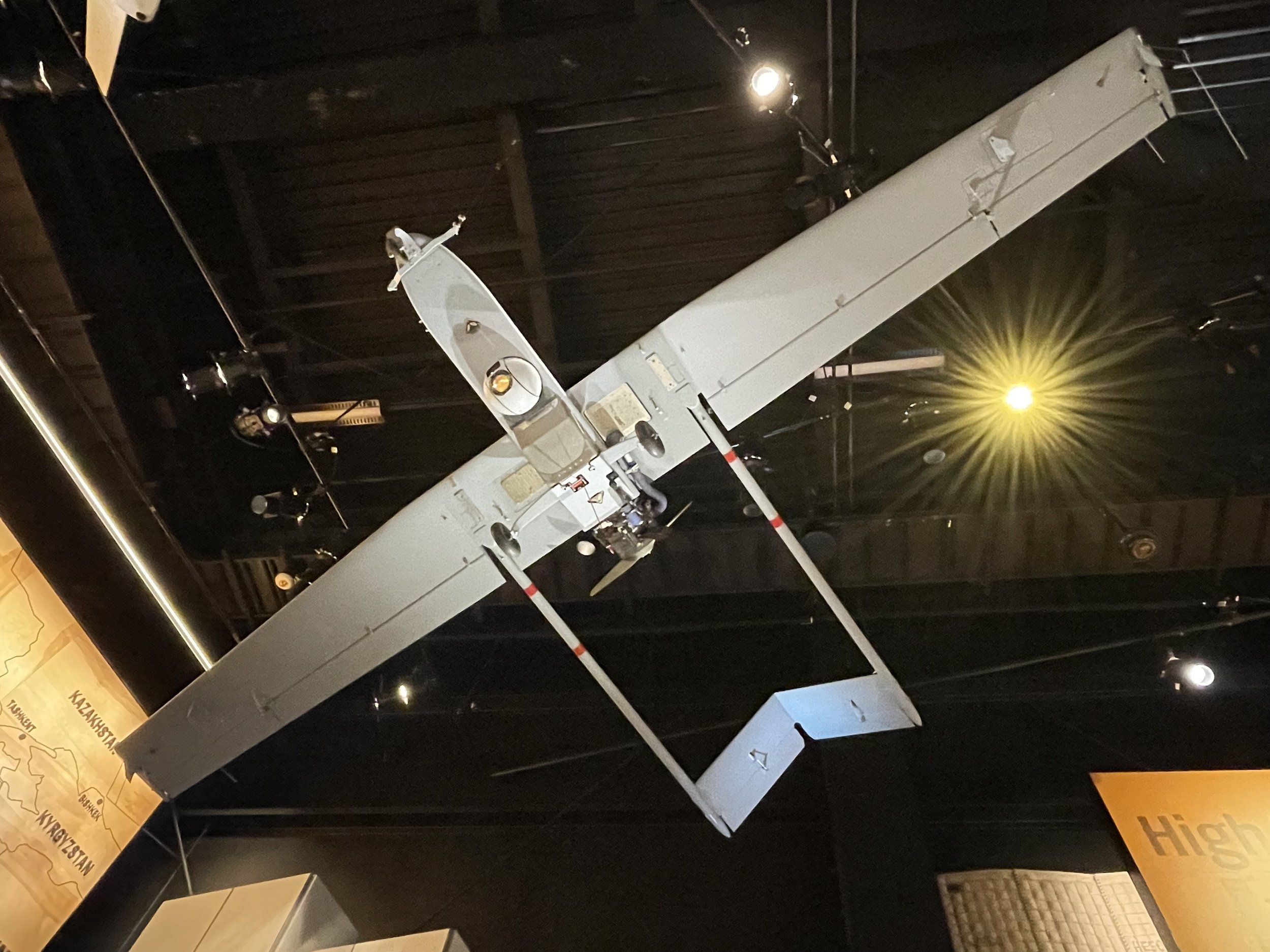

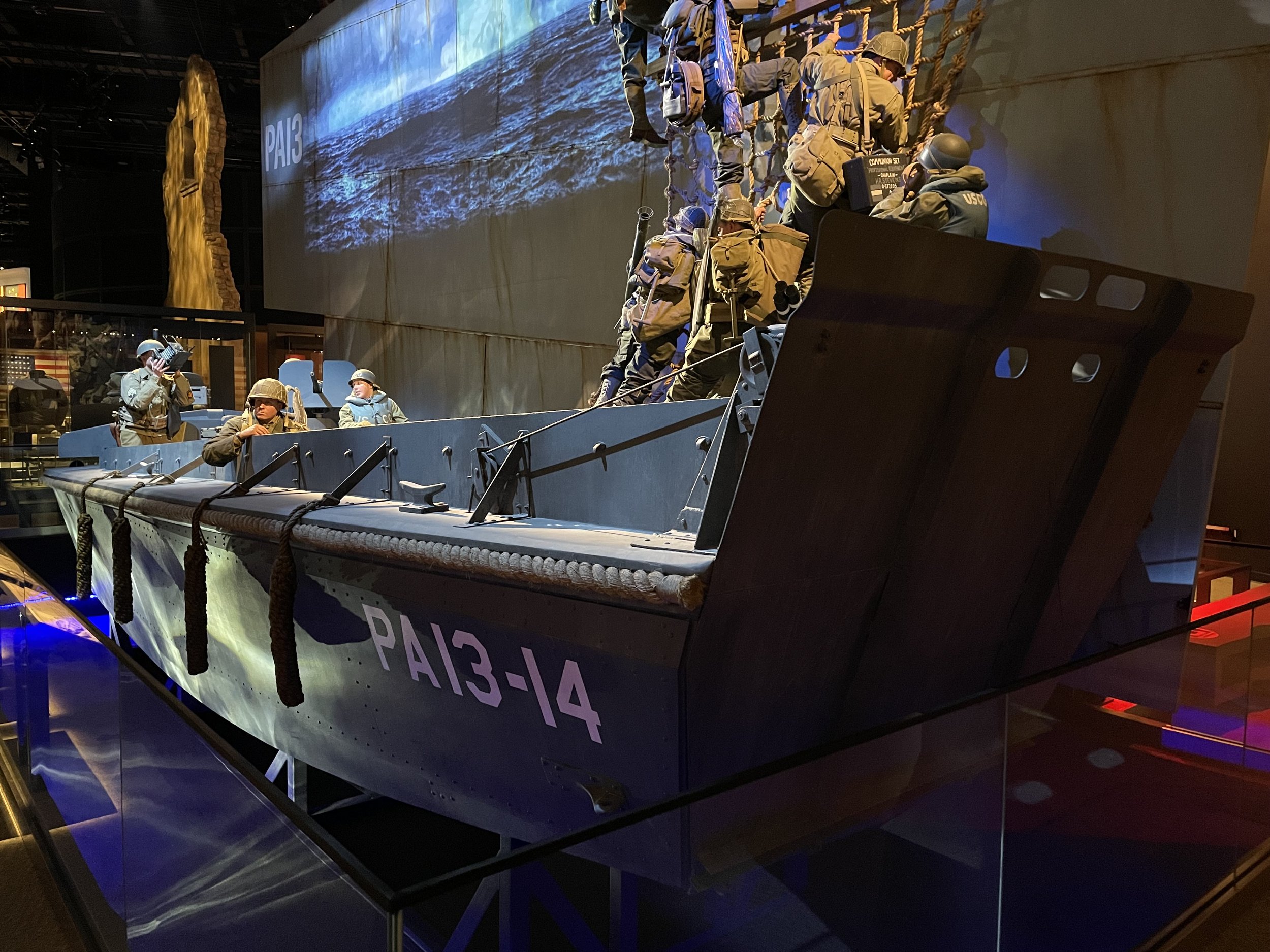

B.R. Howard's extensive military conservation portfolio includes large macro objects like tank and cannon restoration as well as smaller objects like swords and drums.

About our military artifact conservation services

Our culture’s military artifacts are an important asset to preserve, protect, and share with the community. We’ve worked with many military history museums to conserve objects like firearms, cannons, jackets, swords, and many others. Materials and supplies used on military projects are carefully researched and chosen for the needs of each specific military artifact. If your military history museum has an entire collection that needs conservation work completed, our conservators are skilled in packing and transporting artifacts. We are able to pack and ship (or coordinate shipping) your collection to our facility for assessment and treatment. We also have storage space available for any collections that are not currently on display.

Get a quote

Tell us about your military artifact collection and we can get in touch with you to schedule an assessment or the next appropriate step.